Rollmore Fighting Gear Case Study

How we helped Rollmore succeed

The Customer

RollMore manages a family of eCommerce channels focused on providing training and fighting gear for individuals, leagues and martial arts schools, MMA, Brazilian jujitsu, karate and related communities.

Our main markets are the US and the UK; we also have growing international sales.

We run our own eCommerce channels with in-house product development, marketing, customer support, and a fulfillment operations team.

We used to struggle with scale as we grew. Three years ago, we came across ShipHero and Socket Mobile solutions and have been using these products ever since with great success.

The Challenge

RollMore had 3 challenges to solve:

Accuracy of inventory: Karate Depot sells many SKUs, with many SKU variations that could easily lead to the wrong products being picked or put into incorrect bin locations. Typically, when the warehouse team is dealing with higher order volume (we ship on average a thousand orders per day), they tend to make more errors when reading labels or visually referencing products. Inventory would often be incorrect, with SKUs being put into incorrect locations, leading to more errors when fulfilling orders.

Order picking accuracy: Again, our error rates would increase as order volume and activity volume increased, and we could correlate this primarily to new warehouse employees being unfamiliar with what they were picking, along with taking shortcuts to save time.

It took too long to pack orders: Packers had to click too many buttons for each order, selecting the box, shipping method, printing a label, etc. The added seconds resulted in a lower packing volume per packer, which required us to hire more packers to keep up with demand.

The Application

We needed a robust, easy-to-use, and comprehensive WMS/OMS solution, and after looking into a few stock apps and delivery apps, we decided on ShipHero. We like ShipHero for its comprehensive set of features that help our warehouse manage inventory, pick orders, receive new stock and manage returns.

We regularly handle large volumes of orders, typically in the range of 1k to 3k per day off-season and in the 10k range per day busy season. Using the ShipHero mobile app has made our picking and packing much more efficient.

The Socket Mobile Solution

To get the most out of ShipHero and further improve our efficiency, we decided to invest in a set of dedicated barcode scanners.

After shopping around, we concluded that the DuraScan D700 would be the best tool for our operation's supply chain management. The scanners were easy to integrate into the ShipHero app, easy to use, durable, and offered excellent scanning speed and accuracy. Paired with ShipHero, Socket Mobile barcode scanners have helped us to achieve a 99.87% accuracy rate for fulfilled orders.

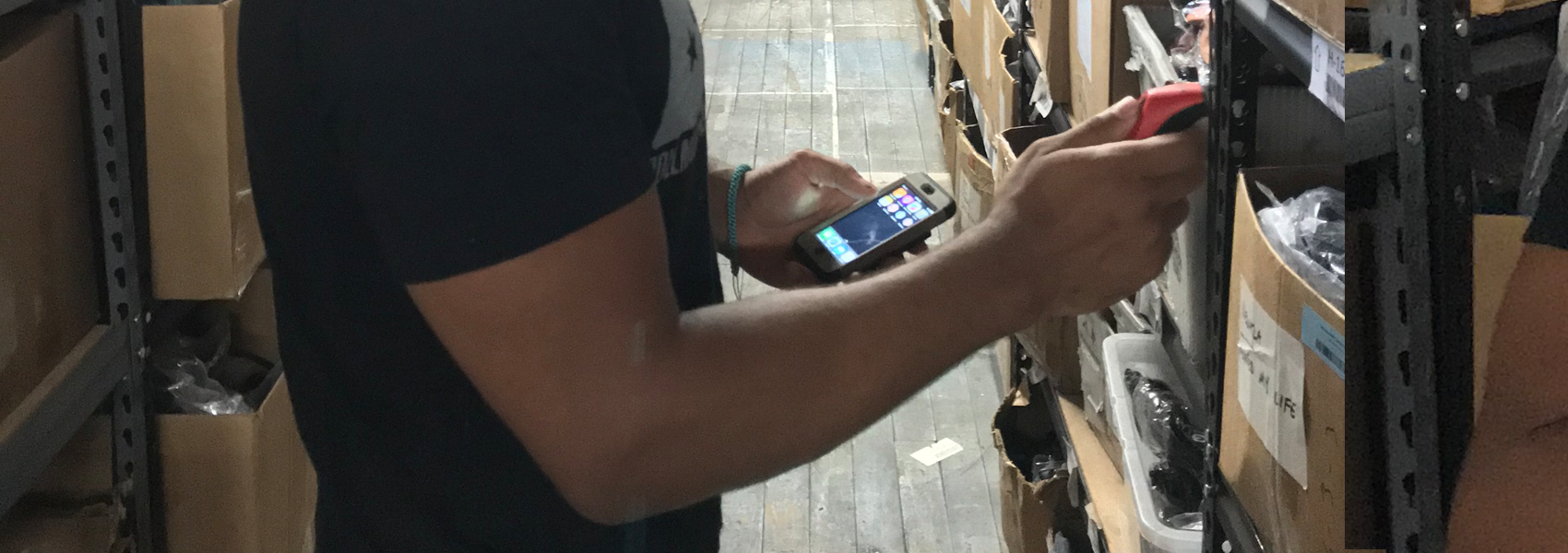

We equipped our warehouse team with a fleet of Socket Mobile D700 scanners. They use them for package tracking: scanning barcodes on locations, boxes, inventory, incoming stock, and returns.

The Results

Our business is all about providing a great customer experience with fast and accurate shipping. By focusing on scaling the speed and accuracy of our fulfillment and inventory management processes, we have significantly reduced opportunities for errors and late orders.

We simply could not have scaled without ShipHero as the backbone of our back-office logistics management. And it pairs perfectly with our Socket Mobile scanners. We've found that Socket Mobile scanners are resilient enough to handle the drops and general abuse of being in a warehouse, as well as easy to use and fast. These great devices have enabled the growth of our business.